Are you looking for Latham electronic product design services for a unique idea not yet available on the market? Need an experienced circuit designer or professional PCB (printed circuit board) design expert to bring your innovation to life? Whether you're seeking a proof-of-concept, schematic and layout review, embedded programming support, or complete end-to-end electronic engineering services, Electronic Design Services for Latham has the expertise to deliver.

Our team has decades of combined experience in electronic design, circuit development, prototyping, and low-to-medium volume production consulting. We also specialize in embedded firmware programming for microcontrollers and SoCs. With deep experience using a variety of industry-standard and open-source EDA tools, we're well-positioned to meet the needs of startups, research labs, manufacturers, and inventors.

Our electronic design journey began in the 1990s using Protel, now known as Altium Designer. Today, while still proficient in Altium for legacy projects, we prefer open-source tools such as gEDA, Lepton-EDA, pcb-rnd, KiCad, and Eagle. Using gEDA’s modular structure, we’ve developed powerful internal tools with Python scripts that auto-generate footprints, BOMs, and price lists by integrating with services like Octopart and DigiKey APIs. These automations reduce project time and cost, improving efficiency for our clients.

Our Latham custom electronics expertise covers a wide spectrum:

- Analog and digital circuit design

- RF design and wireless communication protocols (WiFi, Bluetooth, Zigbee, proprietary long-range RF)

- Microcontroller platforms: TI MSP430, ST STM32, ESP32, FPGA

- Battery and power systems: PMIC, Li-Ion/Li-Po charging, wireless (inductive) charging

- Sensor integration: IMU, accelerometers, gyros, image sensors, lidar, radar, ultrasonic, IR

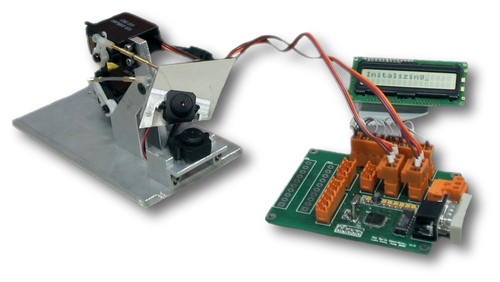

- Motor and actuator control: brushed and brushless DC motors (BLDC), servos, steppers, pneumatics, hydraulics

- IoT device development and wearable electronics (e.g., LilyPad, conductive thread)

We understand that a scalable electronic product often hinges on the firmware layer. A well-selected microcontroller (MCU) or microprocessor (MPU) allows flexibility, reusability, and remote upgrades. We have extensive experience developing embedded firmware and also offer services across:

- Application software development for desktop and mobile

- GUI design for user interfaces on embedded systems and control panels

- Cross-platform development using Linux, Windows, and macOS (typically via VirtualBox or Docker)

- Full-stack web development for connected device dashboards

Our Linux-based development environment, often on Ubuntu/Debian, enables us to run robust development toolchains. Our programming skill set spans C, C++, Python, Bash, JavaScript, and more—allowing us to write firmware, APIs, backend logic, and even full-stack applications when needed.

Of course, no product is complete without physical validation. Our Latham PCB assembly and prototyping process ensures reliable testing and debugging. We typically have PCBs fabricated overseas (China) with a 5-day turnaround, using custom stencils for precise surface-mount technology (SMT). We complete in-house reflow soldering using a reflow oven and perform through-hole and fine-pitch rework with manual soldering tools. Our team is comfortable working with 0603 components and smaller.

Some of Our Electronic Design Services for Latham and Prototyping Experience

Our CTO, Luke Cole, previously worked as a "Robotics Engineer" at Hemisphere GPS (now AgJunction), where he implemented GPS-guided auto-navigation systems for agricultural machinery including tractors and quadbikes. His background includes developing indoor tracking systems for Location Aware Technologies (433 MHz), and he has contributed to advanced R&D initiatives at NICTA, CSIRO, and the ANU Robotics Systems Lab led by Alex Zelinsky.

Lance Cole has also contributed to NICTA and led hardware development projects for military-grade systems at EOS, including the Common Remotely Operated Weapon Station (CROWS) used by the U.S. military—demonstrating our deep capability in high-reliability electronics.

Whether you’re building a custom sensor board, developing an embedded IoT product, or designing the next big wearable device, Electronic Design Services for Latham offers the full stack of electronic design services—from idea to working prototype and beyond.

Information About Latham

Empowering Local Businesses in Latham, Belconnen, and Beyond: COLETEK's Commitment to the Australian Capital Territory

As a thriving hub of commerce and innovation, Latham, Belconnen, in the heart of the Australian Capital Territory (ACT), is home to a diverse range of businesses. From boutique startups to established enterprises, entrepreneurs and small business owners from this area know that a strong foundation is crucial for long-term success. That's where COLETEK comes in – a trusted national company with a local focus on supporting the growth and prosperity of organizations throughout Latham, Belconnen, and surrounding regions. For over decades, we've been at the forefront of the industry, providing unparalleled expertise to an ever-growing clientele across Australia. Our extensive experience has given us a deep understanding of what it takes for businesses like yours in Latham, Belconnen, and the wider ACT community to thrive. By harnessing our nation-wide reach and local knowledge, we're dedicated to helping you overcome challenges, seize opportunities, and drive your company forward. At COLETEK, we believe in the importance of building meaningful relationships with the communities we serve. As a trusted partner for businesses in Latham, Belconnen, and the broader ACT region, we're committed to delivering tailored solutions that meet the unique needs of your organization. Our team's unwavering commitment to innovation, quality, and customer satisfaction has earned us a reputation as a reliable choice for those seeking expert guidance. When you choose COLETEK, you can rest assured that you'll be working with a local company that understands the nuances of doing business in Latham, Belconnen, and the ACT. We take pride in our extensive knowledge of the region's economy, industries, and regulatory frameworks – knowledge we use to inform our strategies and foster lasting connections with your organization. If you're looking for a trusted partner to help drive the success of your business in Latham, Belconnen, or beyond, look no further than COLETEK. With our local expertise, national reach, and commitment to innovation, we're poised to support your growth and prosperity every step of the way. Contact UsOur Clients

Electronic Design Services for Latham – Amazing Customer Testimonials

Skykraft is a Canberra based company designing and developing spacecraft for the delivery of global space-based services. Luke and the team have been very responsive with quotes and delivery of machined parts for our company. Looking forward to working with COLETEK on our space programmes.

We've worked with Luke and the team on and off for the past two years. We've found them very accessible and extremely thorough in their dealings. Their documentation is second to none and we’d have no hesitation recommending them on this basis alone.

COLETEK have been absolutely fantastic in their support and manufacture of various components for us. Our designs are always bespoke, intricate and low volume and it’s great to have an Australian company like COLETEK as a trusted and quality manufacturer for our spacecraft mechanical components and assemblies – which have been flight proven through successful mission operations. Keep up the great work!

We had the opportunity to work with Coletek on the re-work of some complex SMD PCB assemblies during 2019. The work was carried out to a very high standard and we were extremely pleased with the outcome. We would not hesitate to recommend COLETEK for any type of complex technology work requiring high accuracy and professionalism.

Delivered excellence on time, great work and great team, thanks!